INDUSTRIJSKE PUMPE

U našem asortimanu naći ćete širok spektar pumpi za pretakanje i doziranje tečnosti, između ostalog u mašinskoj, hemijskoj, prehrambenoj ili štamparskoj industriji. Nudimo membranske, centrifugalne, zupčaste, dozirne, zavojne, peristaltičke, štapne, krilne i ostale tipove pumpi.

Izmenjivači toplote

Našim klijentima takođe pružamo profesionalne izmenjivače toplote. Izmenjivači se koriste, između ostalog u prehrambenoj, hemijskoj, petrohemijskoj industriji ili energetskim potstanicama. U ponudi su pločasti, cevni, hibridni i lemljeni modeli u higijenskim i industrijskim verzijama. Iz velikog izbora možete odabrati pravo rešenje za svoju instalaciju.

Homogenizatori

Među uređajima koje nudimo su i premium APV homogenizatori serije Rannie i Gaulin, koji poseduju 3A sertifikate i zadovoljavaju najvažnijim važećim evropskim standardima. Ovi uređaji se uglavnom koriste u mlečnoj, pivarskoj, kozmetičkoj i prehrambenoj industriji.

Higijenski ventili

Nudimo ventile proizvođača premium brenda APV SPXFLOW ili drugog proivođača kao odlično rešenje koja se koriste u prehrambenoj industriji u pivarskom, mlečnom ili kozmetičkom sektoru. Ventile nudimo u skoro 20 različitih verzija - leptirasti, zaporni, kuglični, regulacioni, sigurnosni i mnoge druge sa ručnom ili pneumatskom regulacijom.

Filteri

U našem proizvodnom programu imamo FT seriju vrećastih, sa ulošcima I absorbcione a pored toga nudimo sa jednom korpom, dvostruke, sa multi-korpama i samočišćujuće filtere SCF filtere. Filteri se koriste, između ostalog tokom procesa površinske zaštite, galvanizacije ili filtriranjem različitih vrsta medija.

Tapflo Solutions ™

Pouzdanost i sigurnost nalaze se kao najpoželjnije karakteristike uređaja koji se primenjuju u industrijskim procesima. Da bi zadovoljio potrebe kupaca, Tapflo nudi razne sisteme protoka najvišeg kvaliteta po meri I želji korisnika. Naša misija je da obezbedimo tehnička rešenja koja garantuju ispravnu funkcionalnost i stabilan rad u svakom okruženju.

Industrijski Mikseri

IBC kontejneri i standardna burad se često koriste u industriji. Njihova primena je najlakši način za skladištenje i transport raznih tečnosti. S obzirom da je u procesu potrebno, pre upotrebe, mnoge od ovih tečnosti promešati, u prilici smo da vam ponudimo niz namenskih industrijskih miksera.

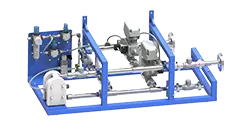

DODATNA OPREMA I PRIBOR

Kao dodatak standardnoj ponudi, nudimo i razne vrste namenskih specijalnih sistema i dodataka iz naše proizvodnje. Kao deo ovih proizvoda nudimo industrijska kolica, pumpne agregate, SKID jedinice, toplotne i zvučne zaštite, kao i razne sisteme za punjenje I doziranje ili pražnjenje kontejnera.